| drying high molecular material/ high polymer materials are top efficient

Ningbo WanHuiTongYang Drying Engineering MFG Co.,Ltd. was established in 1995.

We are professional manufacturer of drying industry in China. It is located in Ningbo, it is a beautiful and convenient water town in Zhejiang.

Cooperating on technology with clients from Japan and relying on the reformed technology from America, Ningbo WanHuiTongYang Drying Engineering Ltd is not only manufacturer, but also from dryer design, equipments manufacture ,transport, up to target place install at customer's project.

Our company has a number of high-level and high-quality professionals, adopts the operation and management methods adapted to the national conditions, organizes and implements production in strict accordance with the requirements of the international quality system, and specializes in the production of drying, mixing, crushing, screening, dust removal, concentration, extraction and transportation equipment.

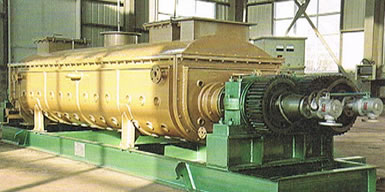

Production types: Wedge type hollow paddle dryer.

working principle

Hollow paddle dryer is a horizontal stirring dryer with conduction as the main component. The main structure is a w-type shell with a jacket. The shell is equipped with a pair of hollow low-speed rotating hollow shafts. The shaft is welded with a plurality of mixing blades, jackets and hollow mixing blades. The shaft is connected with a heat carrier. The two heating surfaces heat the materials at the same time. The heat carrier is usually fed from the middle of the dryer, passes through the surface of the mixing material layer, and then discharged from the other side.

Inside drying equipments Inside drying equipments

The main features of the hollow paddle dryer are as follows:

1. The residence time of the material can be adjusted, and the material with high water content can be processed to obtain the material with very low water content; 2. Typical conduction drying mode, energy saving, high conductivity and high thermal efficiency;

3. Since all the required heat is provided by hollow blades and jackets, a small amount of hot air can be added to reduce the humidity of waste gas, with less dust entrainment, easy tail gas treatment, and no auxiliary equipment such as dust removal.

4. The blade has self-cleaning ability. The blades rotate in reverse direction, and the two inclined planes of the blades repeatedly stir, compress, relax and push the materials, so that the page has a unique self-cleaning ability. The heating surface is constantly updated. The heat transfer coefficient of the blade dryer is higher than any other conduction drying method.

Advantages

Compact structure: the main heat transfer components of the dryer are Wedge typ blades, which are densely arranged on fixed rotating shafts at specified intervals, so the heat transfer per unit volume is relatively high. For this reason, the structure of this equipment is very compact and the floor area is small.

High heat transfer efficiency: due to the continuous mixing and stirring of raw materials, the heating and cooling of the relatively rotating spade-shaped blade and inclined blade surface, as well as the body, ensure that all surfaces in contact with the product can transfer heat evenly.

Self-cleaning performance: since the motion of the blades is relative rotation, they play a continuous self-cleaning role on the nearby internal surface. The products that bind to each other and accumulate on the blades can be removed and re-entered into the production process.

Simple control: the drying process and residence time can be easily checked, controlled and adjusted. They can be set and adjusted separately according to the physical properties of the dried products, and the number of shafts or blades, rotating speed, temperature of heat transfer body and drying time can be set and adjusted.

The dust and odor generated are small: because the gas flow used in the drying process is small, the dust and odor generated are also small. Therefore, the vacuum cleaner or deodorizer used with it is also small or unnecessary.

Suitable for drying products with high humidity: due to the use of paddle drying elements and continuous mixing and stirring, it can dry materials with high viscosity and high humidity. Its structural design avoids the product accumulation at the dead corner and the overheating or deterioration caused by the product accumulation.

There is almost no wear and material loss: the rotating speed of the blade is very low, only 10~40 revolutions per minute, which effectively avoids abrasion and rapid wear of machine tools and equipment caused by abrasion. In addition, the fracture risk of metal materials is also minimized.

Advantages of hollow paddle dryer:

1. Low energy consumption of paddle dryer: due to indirect heating, there is no large amount of air to carry away the heat. The outer wall of the dryer is also equipped with an insulating layer. For the slurry material, only 1.22kg of steam is needed for evaporation of 1kg.

2. Low system cost: with huge heat transfer surface per unit effective volume, the processing time is shortened and the equipment size is reduced. It greatly reduces the building area and building space.

3. Wide range of materials to be treated: different thermal media can be used to treat both heat-sensitive materials and materials requiring high temperature treatment. Common media include: steam, heat transfer oil, hot water, cooling water, etc. It can be operated continuously or intermittently and can be applied in many fields.

4. Small environmental pollution: no carrying air is used, and dust materials are rarely carried. The solvent evaporation of the material is small and easy to handle. For contaminated materials or working conditions requiring solvent recovery, closed-circuit circulation can be used.

5. Low operating cost: the equipment operates normally, only 1-2 people/day. Low speed mixing and reasonable structure. Small wear, low maintenance costs.

6. Stable operation: due to the special compression-expansion mixing function of wedge-shaped blades, the material particles fully contact with the heat transfer surface. In the axial range, the temperature, humidity and mixing gradient of the material are very small, thus ensuring the stability of the process

Sludge dryer

Product overview

The hollow shaft of sludge dryer is densely arranged with wedge-shaped hollow blades, and the hot medium flows through the hollow shaft. The heat transfer area per unit effective volume is very large. The temperature of hot medium ranges from - 40 ℃ to 320 ℃, which can be steam or liquid type, such as hot water, heat transfer oil, etc. Indirect conduction heating, without carrying air to take away heat, heat is used to heat materials. The heat loss is only the heat dissipation to the environment through the insulation layer. The heat transfer surface of wedge blade has self-cleaning function. The relative movement of material particles and the wedge-shaped surface produces a washing effect, which can wash off the attached materials on the wedge-shaped surface, and keep a clean heat-transfer surface during operation. The shell of sludge dryer is W-shaped, and two to four hollow mixing shafts are generally arranged in the shell. The shell is provided with a sealed end cover and an upper cover to prevent dust leakage and collect solvent vapor. A baffle plate is set at the outlet to ensure the height of the material level, so that the heat transfer surface is covered by materials and fully play its role. The hot medium flows through the shell jacket and the hollow stirring shaft through the rotary joint. The hollow stirring shaft has different internal structure according to the type of hot medium to ensure good heat transfer effect.

Sludge dryer is a kind of low-speed stirring dryer which is equipped with agitator in the equipment, so that the wet material department can fully contact with the heat carrier and the hot surface under the stirring of the paddle, so as to achieve the purpose of drying. The structure of sludge dryer is generally horizontal, double shaft or four axis. Paddle dryer is divided into hot air type and conduction type. In the conduction type, the heat carrier does not directly contact with the dried material, but the hot surface contacts with the material. The advantages of conduction type are that the materials are not easy to be polluted, the exhaust volume is small, the thermal efficiency is high, and the volume is relatively small, which is conducive to energy saving and air pollution prevention.

working principle

Driven by the drive system of the sludge dryer, the hollow impeller blade shaft rotates slowly, and the material enters the machine from the feed port, and is transported to the discharge port through the slowly rotating hollow blade shaft. The material is heated and dried by hollow paddle and jacket at the same time. Due to the wedge shape of the hollow blade, the material is alternately compressed (at the wedge inclined plane) and expanded (at the wedge gap) when rotating, so that the material movement on the heat transfer surface is intense, and the self-cleaning effect on the heat transfer surface is strengthened, thus greatly improving the heat transfer coefficient. The hot medium for drying can be steam, heat transfer oil or hot water. The hot medium enters the hollow shaft and blade through the rotary joint. When the hot medium is changed to cooling water, the sludge dryer is an ideal powder cooling equipment.

Technical specification table:

| Specifications |

Wanhuitongyang model |

Equipment Net Weight |

The heat transfer area/dryer area(m2) |

from 80% to 30% water content Capacity of sludge dry (Per hour) |

| 2 |

3W |

2438 |

9 |

140-210kgs |

| 3 |

4W |

4542 |

13 |

182-273 |

| 4 |

5W |

5972 |

18 |

252-378 |

| 5 |

6W |

9037 |

29 |

406-609 |

| 6 |

7W |

14235 |

41 |

574-861 |

| 7 |

8W |

19953 |

53 |

742-1113 |

| 8 |

9W |

25038 |

68 |

952-1428 |

| 9 |

10W |

31421 |

81 |

1135-1701 |

| 10 |

11W |

35983 |

95 |

1330-1995 |

| 11 |

12W |

45048 |

110 |

1680-2520 |

| 12 |

13W |

70368 |

160 |

2240-3361 |

| 13 |

14W |

81362 |

200 |

2800-4200 |

| 14 |

15W |

90436 |

250 |

3500-5252 |

| 15 |

16W |

108057 |

300 |

4200-6300 |

Drying equipments for kitchen waste treatment This drying equipments produced by Wanhuitongyang drying Engineering Co., Ltd. is a key equipment for food waste reduction, harmless and resource treatment. This drying equipments produced by Wanhuitongyang drying Engineering Co., Ltd. is a key equipment for food waste reduction, harmless and resource treatment.

Food waste (biological sludge) refers to food leftovers and food residues produced by restaurants and canteens; organic wastes from livestock industry and fishery food processing can be transformed into non-toxic, sterile and free flowing granular products after systematic treatment, which can be used as feed and fertilizer.

|